Data Analytics

Unleashing the Power of Edge Data Analysis

At emd, we provide a cutting-edge telematics analytics solution that goes beyond simple data collection. Our platform enables real-time edge analysis and historical data logging from multiple data sources, including CAN networks and RS485 interfaces for generators. This allows OEMs, asset owners, and fleet managers to gain deep insights into their equipment's performance, optimize operations, and improve asset lifespan.

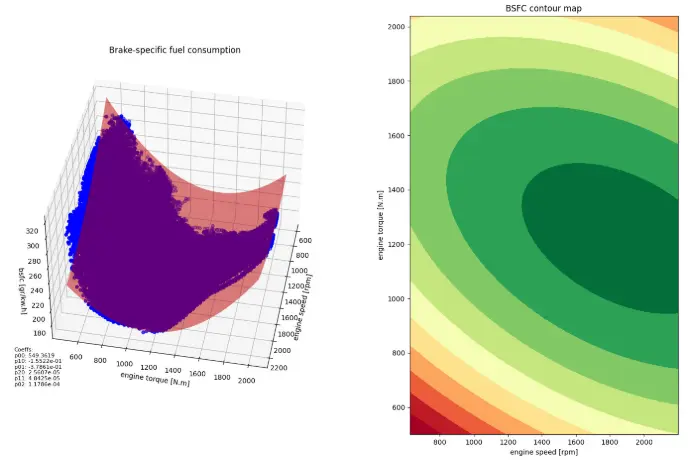

With the ability to capture and analyze data at the highest available frequency, our solution provides a granular and accurate view of asset behavior, empowering businesses to make data-driven decisions that enhance efficiency, reduce fuel consumption, and minimize component wear.

Key Features & Capabilities

Real-Time Edge Analytics

- Process and analyze high-frequency data directly on the device.

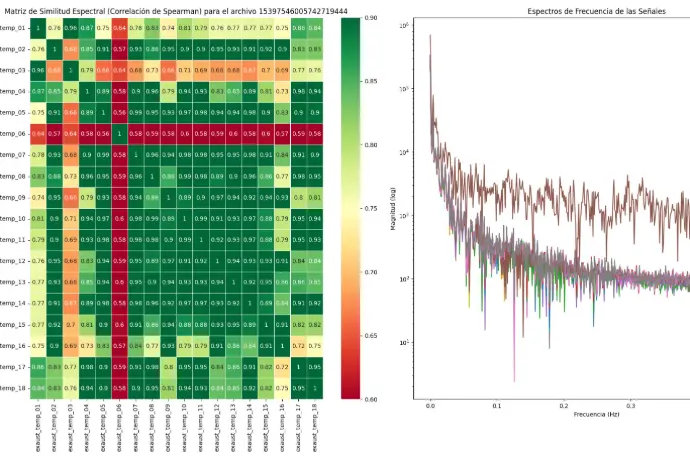

- Evaluate electronic component behavior within an asset to identify deviations from optimal performance.

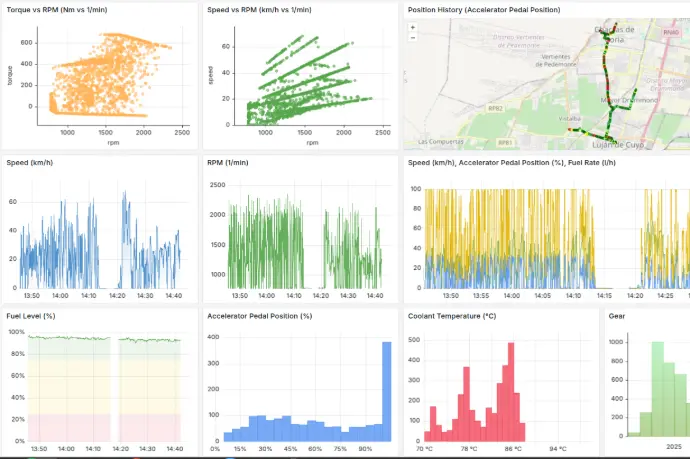

- Monitor operator interactions with the equipment to identify inefficiencies and areas for performance improvement.

- Detect early signs of malfunctioning components, allowing for preventive action before failures occur.

High-Resolution Data Logging & Replay

- Store and retrieve full CAN and RS485 network logs, along with all I/O signals, DACs, GPS, and IMU data at millisecond precision.

- Replay recorded data exactly as it was generated, allowing for forensic-level analysis of asset operation.

- Enable post-event investigation to understand anomalies, reconstruct operational scenarios, and validate system performance.

- Identify operational inefficiencies and train personnel using real-world scenarios derived from historical data.

Predictive Maintenance & Failure Prevention

- Leverage trend analysis to detect patterns that precede component failures.

- Reduce unplanned downtime by identifying failure-prone behaviors in advance.

- Implement condition-based maintenance rather than relying on fixed schedules, optimizing service intervals and reducing unnecessary maintenance costs.

Operational Efficiency & Cost Optimization

- Analyze driver behavior in fleet operations to identify fuel-wasting practices such as excessive idling, harsh acceleration, or improper gear usage, among others.

- Monitor asset utilization trends to maximize efficiency and reduce wear and tear.

- Reduce carbon footprint through fuel usage optimization and emission control strategies.

- Optimize fuel consumption strategies by identifying performance factors that lead to excessive fuel use.

Edge-Based Control Solutions

- Develop customized control logic based on analyzed data to improve safety and asset protection.

- Implement real-time alerts and automated responses on the device itself to prevent damage and enhance operational security.

- Deploy edge-based solutions that automatically regulate equipment operation under specific conditions, protecting both the asset and its operator.

The combined use of this solution with remote connectivity via RP1210 allows for real-time ECU adjustments using proprietary OEM software. This enables fine-tuning of configurations to better adapt components to the actual operational conditions of assets, ensuring optimal performance and efficiency.

Strategic Benefits for Key Stakeholders

For Fleet Operators & End Customers

- Reduce operational costs through detailed fuel consumption and efficiency analysis.

- Improve safety by monitoring and training operators based on actual driving or usage patterns.

- Prolong asset lifespan by detecting operational misuse or excessive mechanical stress.

- Implement smarter maintenance strategies, leading to fewer unexpected breakdowns and reduced service expenses.

For Dealers & Service Providers

- Provide enhanced support services by diagnosing operational issues remotely based on stored historical data.

- Assist customers in implementing optimization strategies for improved asset utilization.

- Offer value-added analytics solutions, increasing service revenue opportunities.

For OEMs & Asset Manufacturers

- Enhance product reliability by analyzing how electronic components function under real-world conditions.

- Design better equipment by leveraging real operational data for R&D and engineering improvements.

- Gain valuable insights into how assets are used in the field, allowing for feature refinements and efficiency optimizations.

Why Choose emd’s Data Analytics Solution?

Get Started Today

Request a Demo

See our analytics platform in action.

Talk to Our Experts

Discover how we can tailor our analytics to your specific needs.

Seamless Integration

Already using a telematics system? We ensure smooth implementation.

Unlock the full potential of your asset data with emd’s Data Analytics Solution.